SHIELD CHEMTRACK

SHIELD CHEMTRACK

Monitor, Review and Take Action

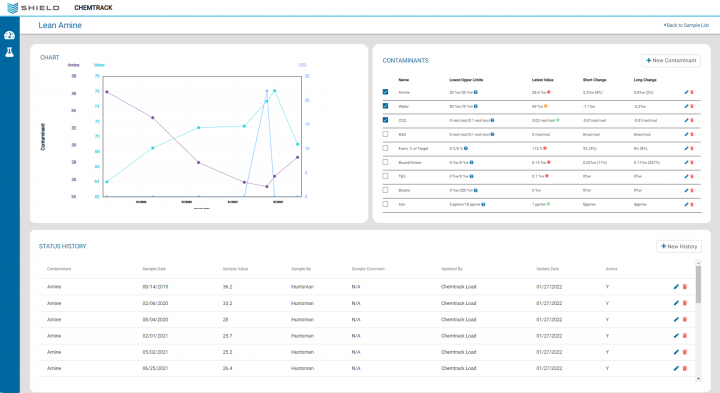

Many chemical facilities operate processes where composition or contaminant levels are required to be analyzed for product control or contaminant impacts such as corrosion or damage mechanisms. An example such as amine contactors and regenerators (Amine Units) at gas processing facilities used to remove acid gases from the hydrocarbon streams. The amine units can offer the most significant Mechanical Integrity challenge in the plant. This is frequently a result of the amine fluid can breaking down and becoming contaminated while operating at high temperatures and with a variety of equipment materials. Most plants conduct routine chemical analysis of the amine fluids but if corrections are not made when contaminants exceed recommended levels, serious corrosion may occur.

The SHIELD CHEMTRACK module is a simple tool to manage the chemical sample data. It has an intuitive interface for entering the analysis results and provides clear graphic representation of the data. In addition, alarm levels may be set for each chemical and contaminant, with automated emails may sent when these levels are exceeded. Standard recommendations may be set for each individual chemical and contaminant and a dashboard provides management information about overall health over your company’s chemical quality.

Product Overview

- Review Performance Across Production Units or Company Wide

- Track and Trend Individual Chemical History

Benefits

SHIELD CHEMTRACK makes analysis data visible and usable

SHIELD CHEMTRACK provides a simple solution to managing chemical analysis data, whether based on reports from the supplier or on site labs.

- The data is readily accessible by all concerned.

- Graphic presentation makes trends visible.

- Email alarms alert teams to out of spec conditions.

- Recommendations available for alarm conditions.